Services

Our company has been operating on the market since 1993. We focused on supplying spare parts for the maintenance of mechanical technology equipment. The main range and commodities were flexible shaft couplings, which we expanded for all sectors of use, in terms of connecting shafts and transmitting torque. During our presence on the market, we have gained experience and skills, which allows us to advise you or propose solution options for your needs. Our largest customers are iron and steel mills, Slovak power plants, magnesite plants, cement plants, lime plants, quarries, waterworks, brickworks, pulp and paper mills, respectively customers using this range of couplings.

For the above-mentioned suppliers, we also deal with the production and delivery of spare parts of a different nature, regarding the production of toothed chain transmissions , conveyor rollers of smaller structures and various other spare parts according to the attached drawing documentation.

Our company also specializes in CNC machining of metal and non-metal materials, TIG/WIG and MIG/MAG welding, production of custom-made gates and fences and surface treatments.

What we do

Milling

A wide selection of machines for milling and machining of metal and non-metal materials.

Turning

Turning and machining of metal and non-metal materials with an emphasis on precision.

Sheet metal burning

Precision cutting of sheet metal and metal materials according to drawing documentation.

Surface treatments through partners

Various surface treatments to improve the durability and appearance of products.

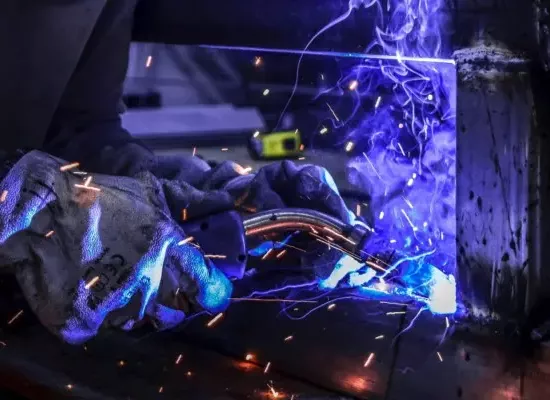

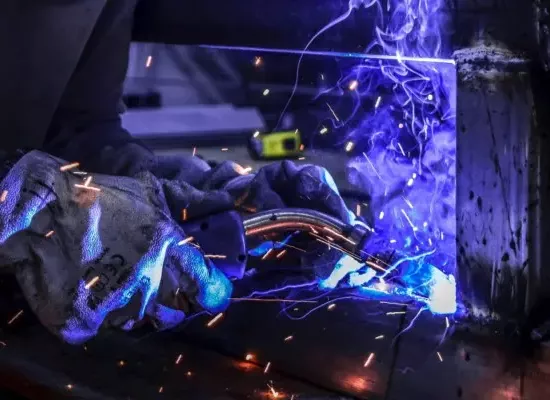

Laser welding

High quality and precision of joining materials with minimal thermal impact on surrounding areas.

Milling

- Our milling services deliver precision and high quality.

- We process a variety of materials and applications.

- Manufacture prototypes or serial parts with CNC milling machines.

- We ensure precise dimensions and smooth surfaces.

Turning

- High precision and quality of machining.

- CNC lathes can handle both simple and complex geometries.

- We work with metals and plastics, we pay attention to detail.

Sheet metal burning

- Precise cutting of metal materials according to technical drawings or customer requirements.

- We use plasma, laser and oxy-acetylene cutting.

- Manufacture of parts of various shapes and thicknesses, from simple cutouts to complex components.

Laser welding

- Fiber laser welding technology is rapidly gaining popularity in the industrial sector and is effectively replacing traditional, less efficient methods.

- With its exceptional precision, flexibility and high operational efficiency, laser welding is the ideal solution for the most demanding industries.

- It is widely used in sectors such as aerospace, automotive, defense, medical device manufacturing, electronics, petrochemicals, telecommunications, energy, automation and outsourcing services.

- Our laser welding ensures high quality and precision joining of materials with minimal thermal impact on the surrounding areas.

Laserschweißen

- Die Faserlaserschweißtechnologie erfreut sich in der Industrie zunehmender Beliebtheit und ersetzt erfolgreich traditionelle, weniger effiziente Methoden.

- Mit seiner außergewöhnlichen Präzision, Flexibilität und hohen Betriebseffizienz ist das Laserschweißen die ideale Lösung für anspruchsvollste Branchen.

- Es wird häufig in Branchen wie der Luft- und Raumfahrt, der Automobilindustrie, der Verteidigung, der Medizintechnik, der Elektronik, der Petrochemie, der Telekommunikation, der Energiewirtschaft, der Automatisierung und im Outsourcing eingesetzt.

- Unser Laserschweißen gewährleistet hochwertige und präzise Materialverbindungen bei minimaler thermischer Belastung der Umgebung.

Mahlen

- Unsere Fräsdienstleistungen liefern Präzision und hohe Qualität.

- Wir verarbeiten eine Vielzahl von Materialien und Anwendungen.

- Fertigen Sie Prototypen oder Serienteile mit CNC-Fräsmaschinen.

- Wir sorgen für präzise Abmessungen und glatte Oberflächen.

Drehen

- Hohe Präzision und Bearbeitungsqualität.

- CNC-Drehmaschinen können sowohl einfache als auch komplexe Geometrien bearbeiten.

- Wir arbeiten mit Metallen und Kunststoffen und legen Wert auf Details.

Blechbrennen

- Präzises Schneiden von Metallwerkstoffen nach technischen Zeichnungen oder Kundenanforderungen.

- Wir verwenden Plasma-, Laser- und Autogenschneiden.

- Herstellung von Teilen unterschiedlicher Formen und Stärken, von einfachen Ausschnitten bis hin zu komplexen Komponenten.

We provide surface treatments through partners

Surface treatments are a key step in the production of parts, improving the durability, durability, aesthetics and functional properties of materials.

Powder coating

- A modern electrochemical method of applying paint to metal.

- It can evenly cover even difficult and inaccessible places.

- The layer is captured in the paint bath using an electric current and solidifies in an oven.

- The result is a thin but durable corrosion protection.

Hardening

- Increases the hardness and mechanical resistance of metals.

- Used in the manufacture of tools, gears and mechanical components.

- Involves heating the material, rapid cooling and tempering to eliminate brittleness.

- Extends the life of metal components and improves their performance.

KTL (Cataphoretic coating)

- Increases the hardness and mechanical resistance of metals.

- Used in the manufacture of tools, gears and mechanical components.

- Involves heating the material, rapid cooling and tempering to eliminate brittleness.

- Extends the life of metal components and improves their performance.

Zinc plating

- Protection of metals from corrosion by applying a layer of zinc.

- Provides resistance to moisture and chemicals.

Anodizing

- Creates a protective oxide layer on aluminum components.

- Increases resistance to corrosion and mechanical wear.

- Provides the possibility of color modification of the material, suitable for design applications.